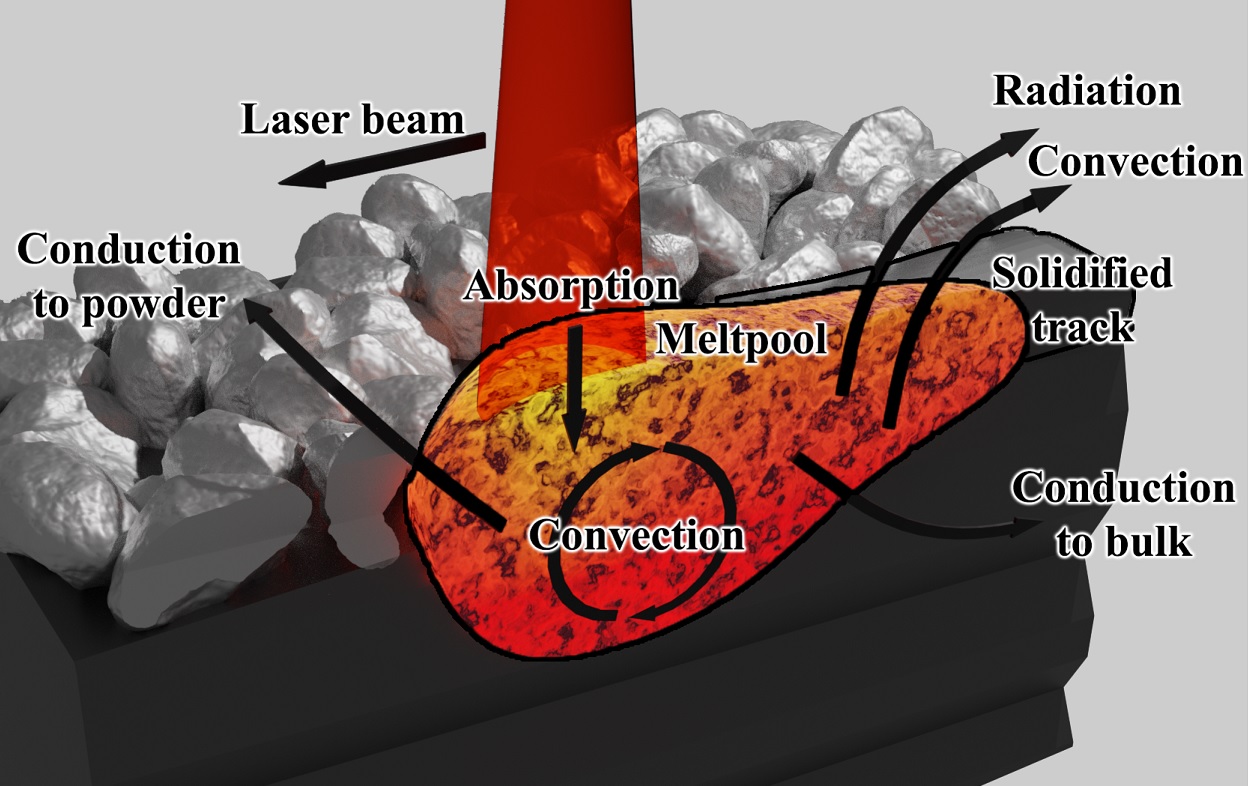

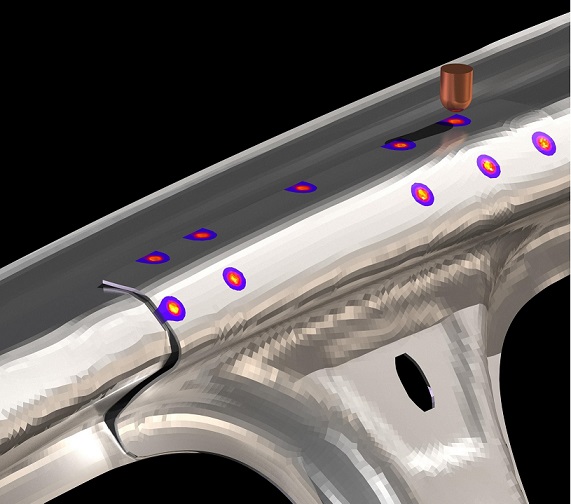

Stress relieving is a heat treatment process that reduces residual stresses in an assembly after welding. This process is important because residual stresses can cause distortion, cracking, and premature failure of the welded structure.

The stress relief heat treatment involves heating the welded assembly to a specific temperature, holding it at that temperature for a specified amount of time, and then cooling it down gradually. The time-temperature curves for heating, holding, and cooling phases are defined based on the material properties and the desired level of stress relief.

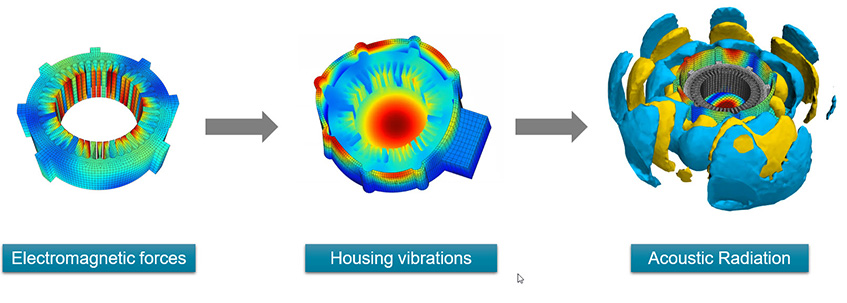

In FEA stress relief modeling, two mechanisms are taken into account: stress relaxation and time-dependent creep properties of the material. Stress relaxation occurs due to the decreased yield stress of the material during heating, while time-dependent creep properties refer to the tendency of materials to deform under constant stress over time.

By using FEA stress relief modeling, our engineers can predict the level of stress relief in a welded structure, optimize the stress relief heat treatment process, and identify potential areas of stress concentration that may require further analysis or modification.